Let You Know What Is a Double Safety Tanker!

Do not forget the original intention, welding is safe. Recently, the Ministry of Transport issued an urgent notice on effectively doing a good job in safety production in key areas such as the transportation of hazardous chemicals, and resolutely curbing major safety production accidents, which makes us have to further examine the importance of "safety".

Since 1982, Shengrun people have always adhered to the original intention of designing and manufacturing high-end and high-quality semi-trailers, and strived to provide customers with more reliable double-safety tankers. Today, let's take a look at what is a double-safety tanker.

What is a double safety tanker

From the aspects of design, manufacture and service guarantee, it provides customers with a tank truck with double safety guarantee. It has five advantages of anti-breakage, anti-collision damage, anti-vibration, anti-leakage and anti-rollover.

See how it does it from the design and manufacturing side

Safe material selection

Shengrun Automobile adheres to high-standard positioning, establishes close strategic cooperation with well-known plate suppliers such as Shougang, controls the source, and selects the best of all plates, with stable quality and more safety and reliability.

safety design

Strategic cooperation with domestic and foreign tank car technical experts and well-known domestic universities, the combination of production, education and research, through the application of the most advanced tank car design technology, make the vehicle safety design achieve the best.

Safe process

▶Introduce international advanced technology, automatic CNC rolling, high rolling precision, no damage to the plate, one-time forming of the cylinder, and stable quality.

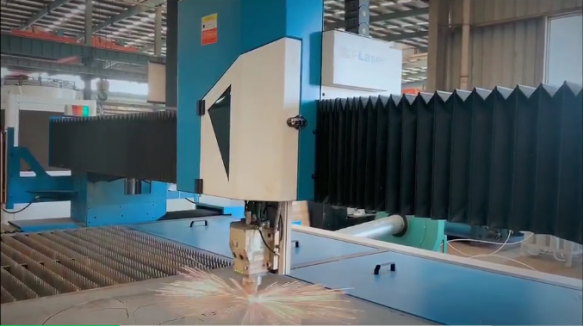

▶ Laser cutting, mirror cut, no defects, no stress concentration; small hot-melt area, small deformation of the plate, higher strength after forming, so that the welding accuracy is more guaranteed.

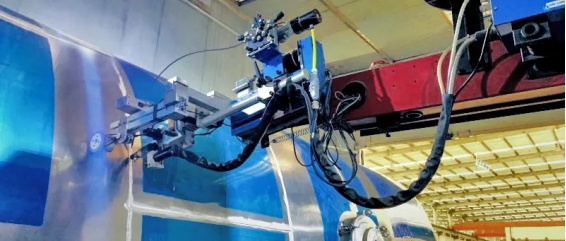

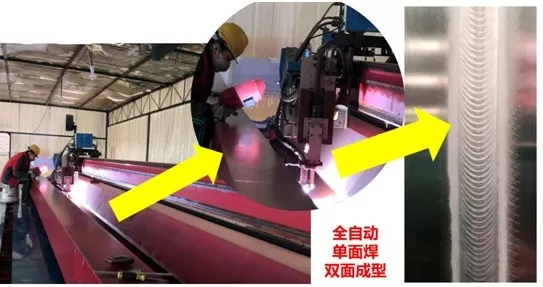

▶The pass rate of X-ray inspection of welding seam is 100%. Robot automatic welding such as special-shaped tank circumferential seam automatic welding, flat plate butt automatic welding, and pressure vessel plasma automatic welding is adopted to reduce welding undercut, incomplete penetration, welding through and other defects. The mechanical properties are stable, the risk of cracking is reduced, and the welding seam is full and beautiful.

safety accessories Relying on its own industry resources, it has formulated various quality standards for spare parts, and has carried out high-quality and standardized configuration of spare parts to ensure that every screw meets safety standards.

Safety quality control

Core advantage: vehicle warranty for 5 years or 350,000 kilometers

1. Anti-breakage

National patent T-beam (patent number: zL 201520863650.9),

10,000-12,000-ton extrusion press

One-time extrusion molding

The bearing capacity and torsion resistance are extremely strong, which are 3-5 times that of traditional L-shaped longitudinal beams.

so that the tanker in the event of a collision accident, Not easy to break, stronger bearing capacity.

1. Anti-collision damage

aluminum plate of Shengrun tank body is customized and rolled according to the European ASME standard.

Absorbs stress and resists impact.

Patented wave board reinforcement (Patent No.: ZL 2015 20862969.X)

Increase the impact resistance of the wave board,

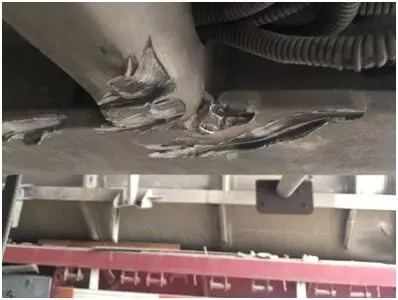

Prevent the tank from tearing due to stress concentration;

Enhance the overall strength of the tank to prevent deformation.

There is a 35cm rear-end collision prevention space (the national standard is 15cm) at the rear of the Shengrun tanker to better protect the tank.

3. Anti-leakage

( 1 ) Robot welding

Shengrun tank body adopts automatic single-sided welding and double-sided forming TIG welding + MIG welding, X-ray flaw detection, and all-round inspection without dead ends, to ensure that the welding seam is 100% qualified and strictly prevent leakage.

( 2 ) 0 clearance clamping and positioning

Simplified plate, head and anti-wave plate are assembled using patented fixtures for clamping and positioning with 0 gaps. The welding quality and weld strength are better than those of the cylinder plate, and they are durable and leak-proof.

( 3 ) Emergency sealing device Subsea valve, automatic closing device, emergency cut-off device, using well-known brands at home and abroad, in line with ADR standards to effectively improve transportation safety.

4. Anti-vibration

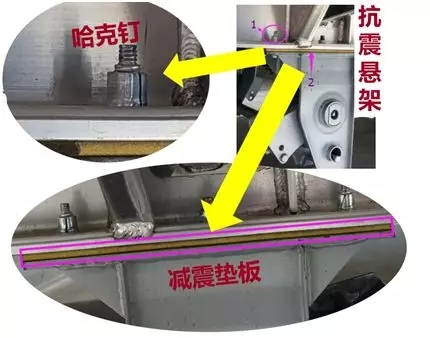

For suspension, Hack nail bolts, press-fit assembly, reduce the stress and deformation caused by welding, and improve the service life of the vehicle base.